Water Wedge VS Electric Heating Wedge

- by Sharry

- November 15, 2024

How to choose the suitable softgel wedge

Softgel wedge also known as segment plays a great matter during soft gel encapsulation.

A suitable softgel segment make the encapsulation process much more efficient.

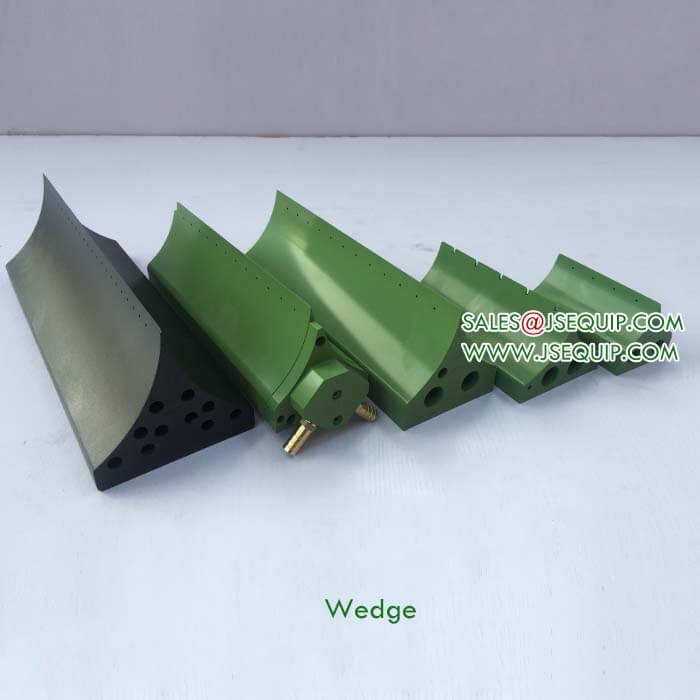

There are mainly two types of softgel wedges. One is Water Circulating Heating Wedge and another one is Heating Element Direct Heating Wedge. We can commonly seen them on gel encapsulation machines of various brands and makes.

The earliest softgel machine uses direct electric heating wedges; then some supplier invents the water circulating wedge that aims for a more even heating transfer on the wedge. They both have their own cons and pros.

Instead of bush around, let’s summarize the advantages and shortcomings.

Water segment advantage: providing a more even heating spread the wedge; the possibility of over-heat to burn the gelatin ribbon is very small.

Water segment advantage: There are spots on the wedge that the hot water circulation cannot fully reach, especially the first and last rows on the die rollers. Therefore, in some cases users tend to have disformed softgel from the first and last rows of the softgel molds. This is because hot water doesn’t fully cover that area. (Of course, disformed softgel can be a result of other reasons too).

Hot water circulation wedge has a relatively poorer heat transfer than the Heating Element Direct Heating Wedge. This limits the speed of the die rollers. Let’s say heater direct heating wedge goes up to 3rpm for one kind of softgel. Then water wedge probably works best at 2.5rpm. Running faster is not good for hot water circulating to transfer heat over segment. Buyers will see most high-speed or servo softgel machine come with heating element direct heat wedge.

Then what is the disadvantage of eating element direct heat wedge. It is not that good in having even heating. But for many users, it works well too.

In a word, it is not correct to say which is better. Users should choose what most suitable for their softgel manufacturing.

Contact JOYSUN for your softgel manufacturing issue, we are happy to serve.