Automatic Deaeration during Gelatin Melting| Softgel Manufacturing

- by Sharry

- June 13, 2022

Automatic Deaeration during Gelatin Melting

What are the facts to consider during softgel gelatin melting in manufacturing?

Gelatin melting is an important step in the preparation of shell material for softgel encapsulation machines. Proficient operators, know well how to control the temperature, time, vacuum, and pressure during gelatin melting. Here we will focus on one crucial step-‘deaeration’ also known as ‘de bubble’ or ‘defoaming’.

During gelatin, it will generate a lot of bubbles while mixing and melting. Those bubbles are big and sticky, not easy to break. In the conventional gelatin melting process, deaeration is mostly operated by workers manually. When the bubbles come up to the rim of the tank lid, the worker breaks the vacuum condition of the gelatin melting tank, so that the bubble will break due to pressure change (The gelatin melting is done under constant vacuum conditions).

By manual debubble operation sometimes causes problems as below listed.

1. High labor intensity

Constant observation of the bubble level inside the gelatin melting tank is required for at least 15-30minutes. The worker has to open and shut valves on tank frequently in order to break the foam inside.

2. A high rate of malpractice.

If the operator forgets to open/close the valves alternatively, the inside gelatin bubble might overflow out from the tank. Those gelatin bubbles might enter the pipeline, easy to cause pipe blockage, and is difficult to clean. If the cleaning is not timely, there will be contamination. Not only increases the cleaning workload, but it also affects the production schedule.

With the development need of continuous work mode in softgel production line, Joysun has developed our own automatic deaeration system to cut down labor force wastage and to solve above-mentioned issues.

Softgel Gelatin Deaeration Working Process-Demo Video

Joysun special made foam sensor is installed on the gelatin melter, together with our own programmed controlling system, the foam sensor will sense the level of bubble inside the tank. Signals are feedback to PLC to activate valves to open and close automatically. Repeating such actions till the debubble process is done. Our automatic gelatin deaeration is interactive with, vacuum degree control, temperature change, bubble level, and melting time four facts at the same time. So it is not just about sensing the foam, it works well to control all aspects that gelatin melting requires.

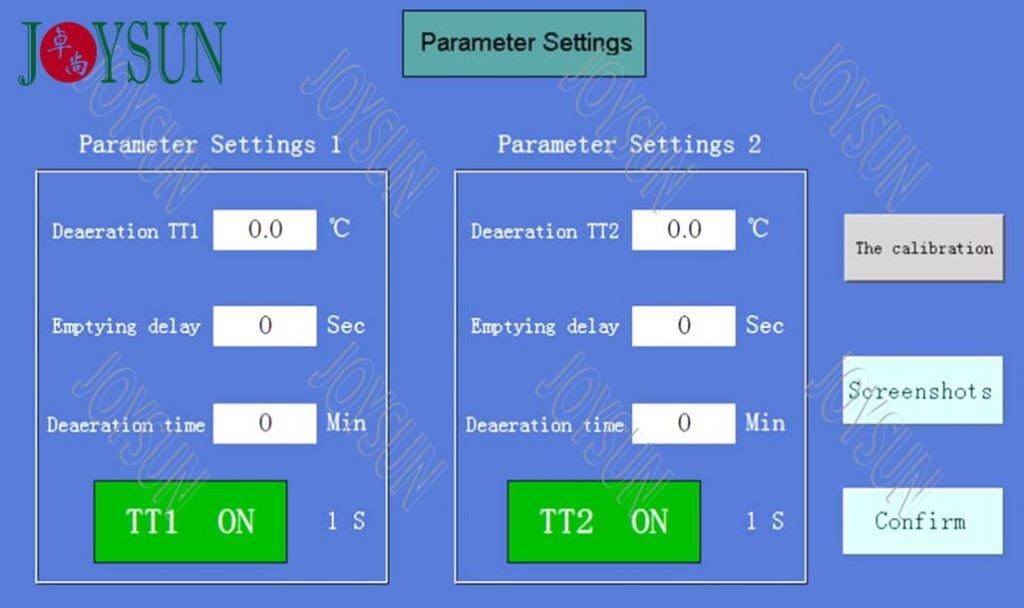

The usage of gelatin automatic deaeration system

The use of such a system is very easy, we have combined all information into the operation panel, and most values are pre-set, with no need to change at all. By simply inputting some data, the gelatin melting system will carry out steps one by one automatically. There is bubble alarming, automatic vacuuming and venting, finish signals and etc.

The best part is that Joysun can not only provide such a system for a new gelatin melting tank but also renovate and improve your old gelatin melting system.

Contact us for your softgel projects! We are able to design an automatic softgel production line and continuous working mode softgel manufacturing to save gelatin service tank and medicine transfer tank. By the continuous softgel working mode, we can save you so much cost in softgel equipment and in cleaning.