Description

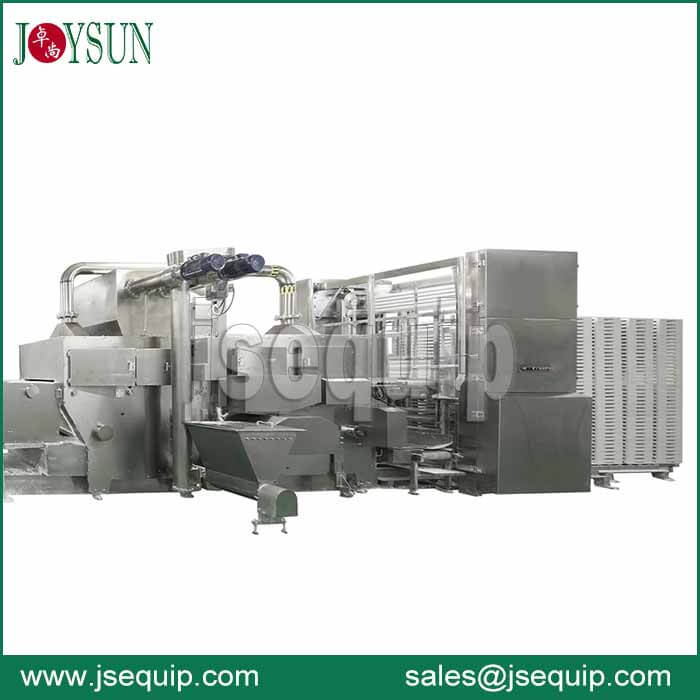

Gummy Coating Machine| Sugar and Powder Coating

There are mainly to purposes of gummy coating machine. One is to coat sugar on the gummy to make it a sugary exterior. Another one is to apply powder onto gummy surface, making it less sticky. There are users also spray oil/wax onto gummy candy, for this purpose, polishing/waxing machine might be more suitable.

According to the different agents we used on the machine:

Sugar Coating Machines: it involves a rotating drum where gummies are tumbled while sugar is gradually applied.

Powder coating machine: same structure with sugar coating machine, only we use powder such as starch-based powder as agent.

Oil Coating Machine: the coating drum also can be used to spray oil on candy surface by adding oil bucket and oil spray gun.

Capacity of the coating machine:

Joysun powder and sugar-coating machine has hopper for coating agent which is speed controllable. The auger in the hopper can control the speed of coating. The machine is suitable for production need from 150KGS-600KGS, wide application.

Factors to consider:

Joysun usually choose flat belt conveyor instead of conveyor with baffles in the middle. This is because many gummies will be sticky. To make the gummy fall into coating drum easier, a brush is necessary to do the job. So, in JS belt conveyor, there is always a brush at the end of conveyor to help gummy comes off.