Description

Brief introduction

JS Softgel Size Sorter is an automatic softgel sizer to pick out bad shape softgel capsules. It’s suitable for symmetric shapes such as round, oblong, oval, and tube softgel. Soft capsules with unqualified geometry will be eliminated by adjusting the distance between the separation rollers. It’s suitable for sorting the softgel which is spherical, cylindrical, oval, tubular rotary body shape. Auto Softgel Size Sorter can be used in the pharmaceutical, health food, cosmetic, and paintball industry.

Demo Video

New Characteristics Compared to Old Model Softgel Sizer

JS softgel sizer was newly updated in 2020, with improved points as below:

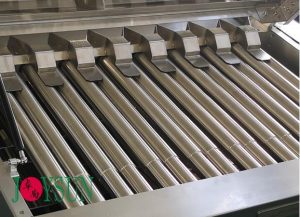

1. 8 pairs of rollers, means 8 softgel channels, currently the most stable model

2. faster speed compared with the old version.

3. bigger and wider hopper, with vibration beneath; ensure no softgel clog and easier to fall down.

4. improve discharge channel, better than old plastic conveyor type.

5. softgel size can be input from the Touch screen directly, instead of micro-adjusting on the machine. E.G. 10mm diameter, input 10mm+0.1mm tolerance is fine); Most softgel sorting machines on market cannot do this.

6. manual adjustment function is still available as well as the auto setting.

Sorting principle:

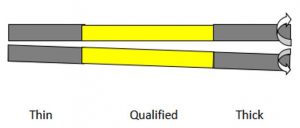

the size of the gap between the optical axis and the stepped axis is used to sort the capsules. The rotation of the optical axis is different from that of the stepped axis, so the capsule is rolling on the axis.

Adjust the middle section of the stepped shaft to reach the required size, and the motor drives the roller to rotate, so that qualified products are selected in the middle section, and small and large unqualified products are missed at the top and bottom. The roll gap size can be accurately adjusted through the digital display. The number can avoid measuring the roll gap size each time. Through the above adjustments, this sorting machine can be used for various types of capsule sorting.

There is a big opening at the end of the roller pair, and there is an angle for each roller pair, the rollers of each pair rotate at a different speed, so the twins will fall down without problems.

Vacuum Loader for Capsules Feeding

Capsules vacuum loader consists of a vacuum pump (no oil, no water), a vacuum hopper, a filter (with polyester film filter, PE filter, 316L stainless steel filter, or titanium filter to choose from), and a compressed counter-blow device, pneumatic discharge door device, automatic material level control device, stainless steel suction nozzle, conveying hose, etc. The entire system is reasonably designed and beautifully manufactured.