Quick Guidance for Purchasing Softgel Die Rolls

What is a softgel die roll?

Softgel die roll is the mold on softgel encapsulation machine, which works to mold various shapes and sizes of softgel capsules upon the cavity design. E.G. a cavity 2#OV can make Oval shape softgel with about 160mg liquid filling inside. Die roll set installs at the very center of softgel machine. Its importance cannot be overrated during encapsulating.

What in a full set of die roll?

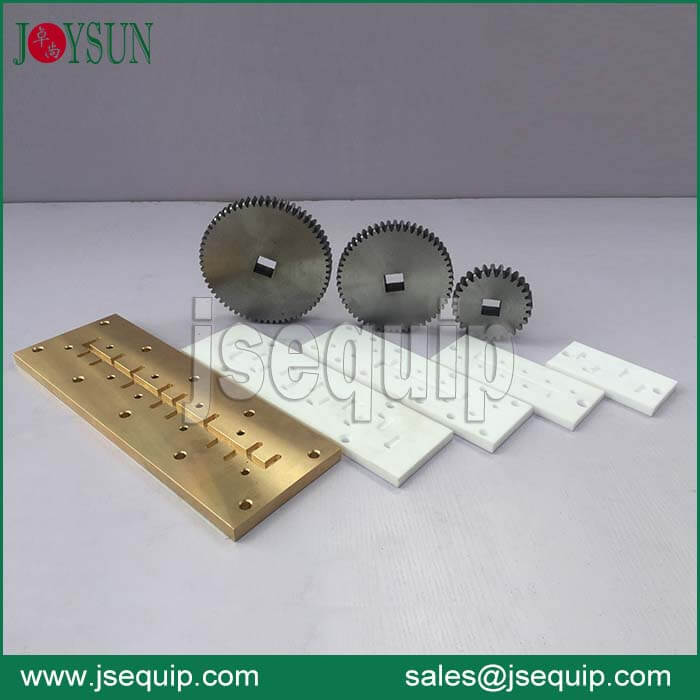

A full set softgel die roll mold consists of two rolling dies, one gear, one wedge, one distribution plate.

- Rolling Dies: mainly made of aviation aluminum, currently the best quality of all aluminum materials. There are many cavities of various sizes and shapes on the die surface. The surface of die is sandblast processed to have a long service life, and anti-oxidation.

- Gear: when replacing dies, the gear needs to be changed as well for a correct injection time. Otherwise, the injection and encapsulation cannot be simultaneous.

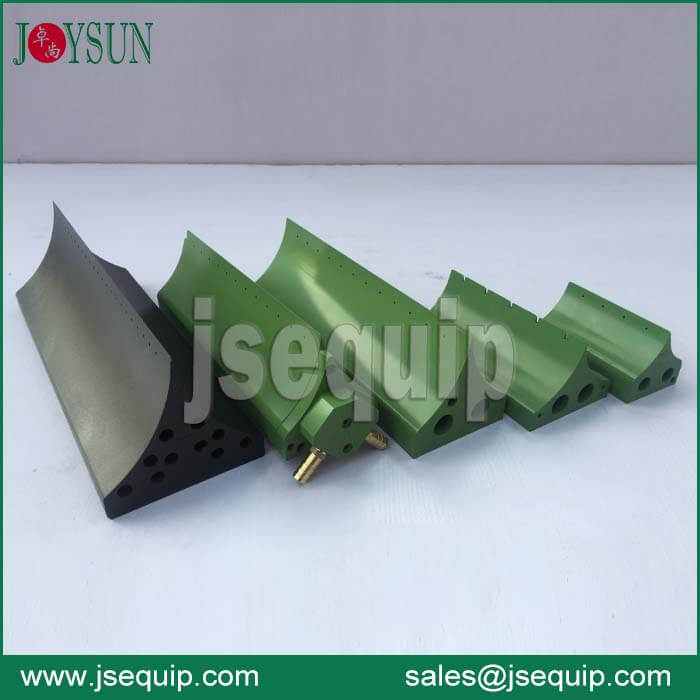

- Wedge: it is called this way due to its shape. It is made of brass and coated with green or black colors. There is a line of small holes (injection holes) at both rims of the wedge.

- Distribution Plate: a part with grooves and hole to fit the injection time.

- Package: we put them all in an AL box suitable for airplane carriers.

How many types of rolling dies?

Shapes and sizes speaking, there are too many types of softgel rolling dies. So here we do not define them upon shape or size. I’d like to break dies into three types single lip, double lip, and triple lip.

- Single lip or single-step refers to there is only one cutting edge around the cavity; this is mostly used for oil softgel like fish oil, vitamin E and etc; Most common and easy softgel dies.

- Double lip dies is proved to be better for paste and suspension softgel in which the medicine is stickier and higher viscous than oil.

- Triple lip dies are more suitable for veggies softgel, especially starch powder, and tapioca softgel. We have made many sets upon users’ requirements.

There is a side shooting and bottom shooting wedge difference in the liquid performance during encapsulation.

How do softgel rolling die molds influence the capsule shape?

A good pair of softgel dies matters greatly in softgel manufacturing.

Rolling dies match with each other precisely; groove, cavities processed by milling machine or lathe should perfectly synchronize. Cutting edge/rim surround cavities should be the right height to cut off gelatin ribbon; For vegetable/vegan/veggie softgel, the cutting edge will usually be higher than gelatin soft gel. Wedge and guide plates should match; bottom shooting wedge, side shooting wedge, electric heating wedge, and constant water heating wedge is improved to make various softgel series.

How to buy softgel molds to fit your own softgel machine?

With Joysun makes your die roll purchasing quite easy as long as the user can provide below-listed data:

Current machine brand and model (if Joysun’s machine, then no need);

Dies’ diameter and length.

Softgel capsule shape and filling quantity in mg/ml.

Filling material: either oil, suspension, paste and etc.

Based on the above info. We can design drawings and make offers.

Feel free to contact us for quick pricing.