Description

Auto Gummy Counting Machine

Introduction

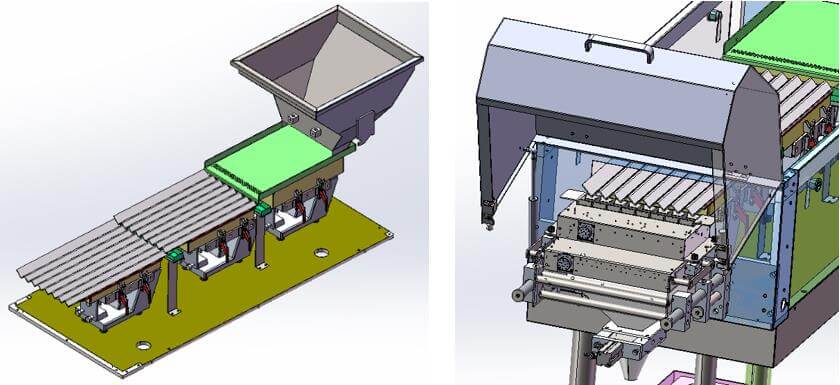

JS auto gummy counting machine is to count and fill gummy candies into bottles, bags, sachets, jars, and other kinds of packages. It counts gummy piece by piece. Each counting channel is equipped with independent vibration to ensure accurate counting and reduce the influence of other counting channels. This gummy counter machine is a stand-alone model and is also compatible with an automatic packaging line, and OKAY to respond to the MES system.

Gummy Counting Machine Features

- Not only suitable for just gummies but also applicable for solid objects such as tablets, pills, capsules, and special-shaped tablets. it is easy to switch between different objects and easy to adjust.

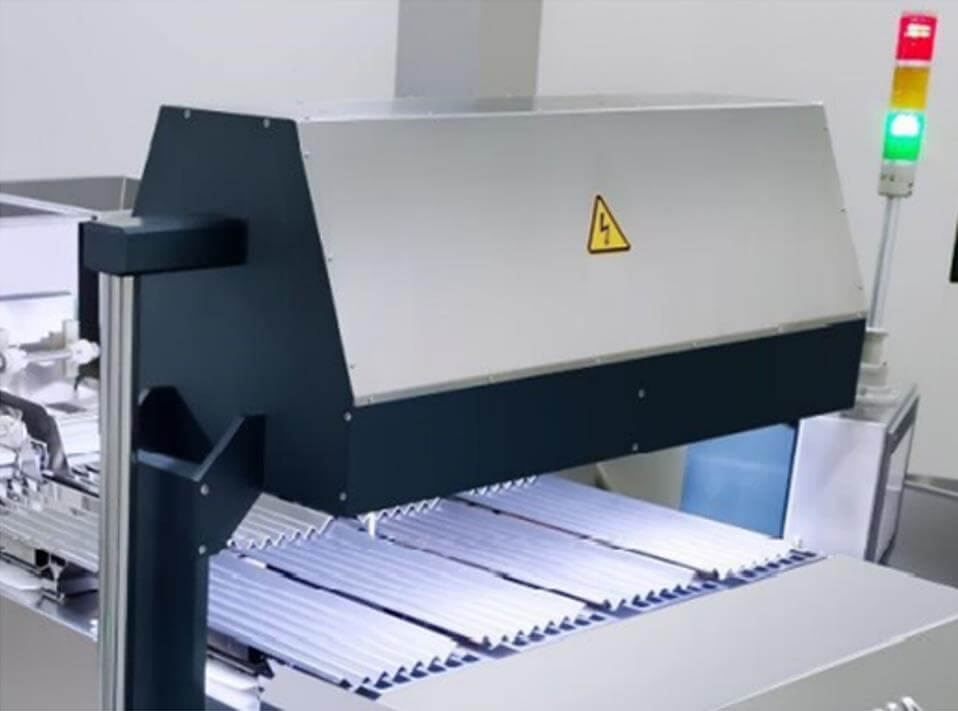

- High accurate counting, using an independent optical detection system to ensure accuracy at a high counting speed.

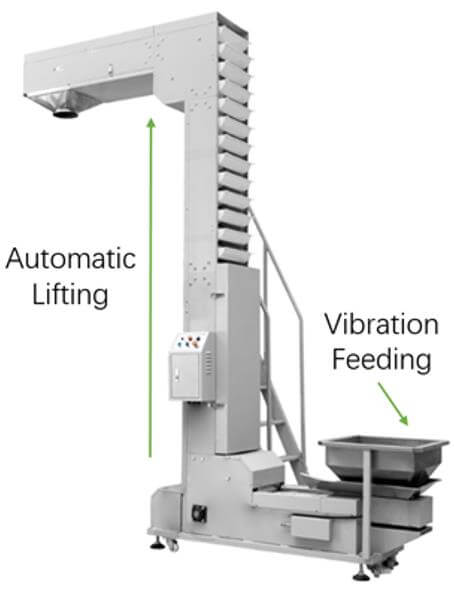

- Multi-stage vibrating feeding is adopted, and the speed of each stage can be adjusted independently so that the gummy moves faster in a more uniform and smoother manner.

- The surface is made of 304 stainless steel and is non-toxic, chemically stable, food-grade, easy to clean, and has no dead ends.

- There are photoelectric sensors for bottle lack and bottle blockage detection. It can effectively control the normal operation of the entire system, stop automatically when there is no bottle or bottle blockage, and run automatically after the alarm is cleared.

- Simple operation, intelligent design, and various operating parameters can be set directly on the HMI according to needs.

- Automatic fault diagnosis, comprehensive real-time monitoring, alarm, and display.

Related Gummy Packing Equipment

One Gummy Packed in One Sachet

Considering the stickness performance of gummy, some users prefer to pack one gummy into a small bag.

Gummy Counting and Bag Forming

The machine is able to make a pouch using rolled composite film. At the same time, gummy is counted piece by piece accurately. When the pouch is formed, the gummy drops into pouch. The quantity of gummy counted into bag can be set from touch screen.

Gummy Counting and Packing into Standup Bag Machine

The Gummy Counting and Packing into Standup Bag is a compact equipment to combine counting machine and bag filling and sealing machine into a set.