Description

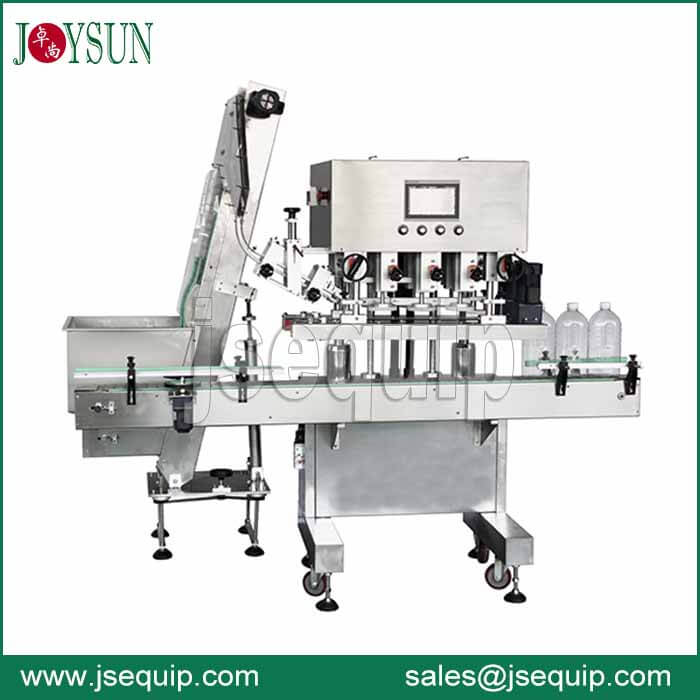

Induction Aluminum Foil Sealing Machine

JSR-4000 electromagnetic induction aluminum foil sealing machine is a new generation of sealing equipment that replaces the backward technology of cork stopper and wax dipping. It is an ideal sealing device that uses the principle of electromagnetic induction to instantly generate high heat to the aluminum foil on the bottle mouth, thereby fusing the aluminum foil to the bottle mouth to achieve the purpose of sealing.

After sealing with an aluminum foil sealing machine, the product has good moisture-proof and mildew-proof effects, so as to achieve the purpose of prolonging the product storage period and anti-counterfeiting. Printing a trademark on aluminum foil can also effectively prevent the production of counterfeit products. Specially used in the sealing process of medicine, pesticide, food, cosmetics, lubricants, and other industries.

The material of the container can be polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyester (PET), polystyrene (PS), glass, etc., and cannot be used for metal bottle bodies and caps.

Induction Aluminum Foil Sealing Machine Features

- The Induction sealing machine has a wide range of applications. The standard type of sealing machine can meet the 120 ~ 150mm diameter bottle mouth sealing. It is easy to switch between different specifications and easy to adjust.

- The overall machine is made of stainless steel, which is beautiful and meets GMP requirements.

- The double cooling system provides better protection for long-term stable operation of the equipment: forced water cooling inside the radiator, super-strong external air cooling, cooling performance more than 20% stronger than other similar sealing machines, so that the hot sealing machine can work stably for a long time, to achieve good and high quality sealing result. The sealing height can be applied to bottles of various heights by easy adjustment.

- Automatic protection: when the whole machine is over temperature, over current, and overpressure, the high frequency will automatically stop heating to realize the protection function;

- Built-in intelligent power supply system to ensure constant power output can work normally under grid fluctuations.

- Optional non-aluminum foil rejection mechanism can be selected to prevent unsealed products from flowing out of the production line and safe to use.

- Flexible application, with automatic bottle separation function, can be produced in a single machine, can also be used with or embedded in the assembly line, suitable for the production of mass production products in the assembly line.