How many types of gummy molds are available?

- by Sharry

- April 7, 2023

How to Choose Molds for Gummy Molds?

There are various of gummy in the market that has appealing look and in so many different shapes and sizes. The most common one might be the ‘bear’ shape. With the development of gummy manufacturing, especially when gummy candy also takes nutritional ingredients into consideration during gummy production; the choices become even wider.

So now we see all kinds of good-looking gummy candy in supermarkets, so many shapes such as water droplets, bears, flowers, stars and hearts and etc., How are these shapes made?

Before we discuss this issue, we should know what kind of equipment produces gummy. There are two types of machines that can make gummies, one is the starch mogul (this type is not discussed for now), and the other is the gummy depositor. Let’s briefly understand the metal gummy depositing machine. How does the gummy depositing machine work? The simple understanding is that the gummy liquid is filled into the mold through the depositing head, and after a certain period of cooling, de-molding to get gummies.

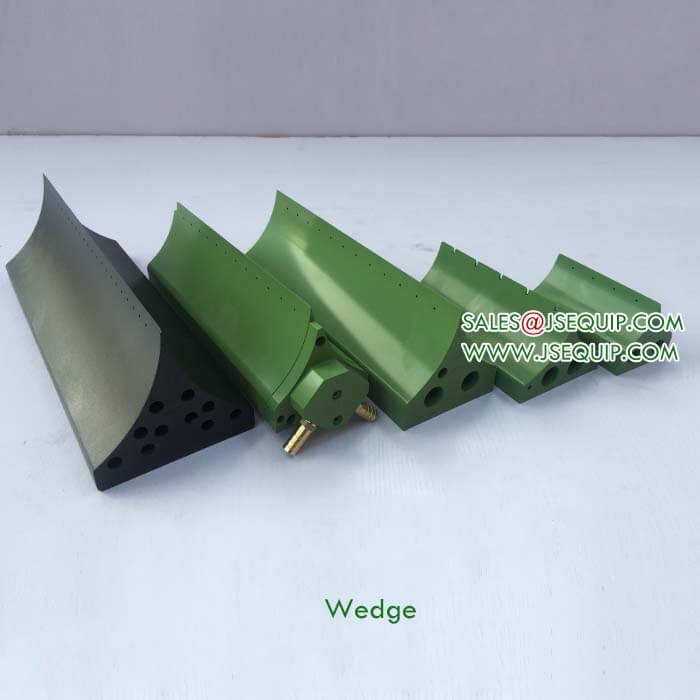

The gummy mold is what determines the shape of the candy. It is also what we want to discuss here. There are three kinds of gummy molds used most on gummy depositing machines, namely: metal flat mold, silicone mold, and 3D mold.

How to choose the right mold for gummy production? What are the advantages and disadvantages of each mold?

First of all, the metal flat mold (pictured above) is the most common. The gummy made by this mold has one side that is three-dimensional and the other side that is flat. The purchase price of this mold is also the cheapest. It can be made in various shapes with almost no shape limitation. But the only flaw is that the candy makes on only one side is three-dimensional. If the gummy manufacturer has high requirements on the shape of the gummy, maybe the three-dimensional mold is more suitable for them. (as shown in the figure below).

Using 3D molds, we can ensure that all aspects and angles of the candy are three-dimensional. This kind of mold is 20% to 30% more expensive than metal flat molds in terms of cost. Generally, a gummy with relatively heavy grams is suitable for three-dimensional molds. For example, if the produced gummy weighs only two or three grams and is made into a 3D shape, the resulting gummy will appear very small, and because of its small size, the designed shape will not be obvious. We generally recommend that gummy with a single weight of ≥6g using three-dimensional molds.

Finally, let’s introduce silicone mold, why there are silicone molds for gummy?

What are the advantages and disadvantages of silicone molds for making gummy?

The shape of the gummy made by the silicone mold is almost the same as that of the metal flat mold, so why do some manufacturers choose silicone molds? Here we are going to talk about the demolding of gummy. Gummy needs to fall off from mold cavities, this is the process of demolding.

When we use metal flat molds to make candy, we need an ejector pin to push the gummy off the mold. Therefore, there will be a shallow mark on the flat side of the gummy. (pictured below). The small round mark is not very obvious, mainly depends on whether the user can accept it or not. While we use silicone molds to make gummy, there is no such problem.

In addition, the existence of the ejector pin structure on the metal molds makes the cleaning process more difficult than in silicone molds. For a company that has relatively high cleaning requirements, better choose the silicone mold.

Disadvantages of silicone molds: its service life is not as long as metal molds. Demoulding is not as easy as metal molds either due to there is no ejector pins. Using silicone molds, some shapes of gummy are easier to peel off the mold, and some shapes require human intervention to come off smoothly. In the past, due to the limitation of engraving technology, silicone mold can only make simple shapes. But with the development of technology, now silicone molds can also make gummy candy of various shapes and sizes.

From the perspective of the cost of these three molds, metal flat molds are the cheapest, followed by silicone molds, and the most expensive is metal 3Dl three-dimensional molds. Of course, the shape of the three-dimensional candies must be better. The production company should choose the most suitable gummy mold according to its own market target, market classification, budget, production plant and equipment cleaning.

Should you have candy gummy mold needs and related questions, please feel free write to us.